20.07.2021

Protection against explosions

Kayser Group from Einbeck wants to make electric vehicles safer

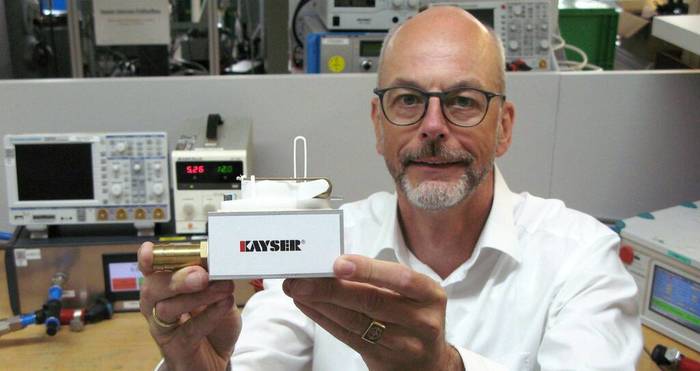

Einbeck – The explosion of batteries in electric cars is to be prevented by an element that the Einbeck-based Kayser Group plans to launch at the end of the year. “If electromobility catches on, we will sell hundreds of thousands of our Kayser Guards every year,” expects head of development Heiko Freter.

“The lithium-ion batteries of an electric car are located in a hermetically sealed metal housing between the front and rear axles,” explains Freter, a graduate engineer. The housing protects against water and dirt. The problem is that if a short circuit occurs, for example as a result of an accident, the batteries heat up and release large quantities of gas in a short time. If it cannot escape, the housing explodes.

“Such rare explosions can also occur in the batteries of smartphones or pedelecs,” Freter knows. Car manufacturers want to protect the vehicle occupants. These must leave the crashed car quickly in any case. Burning lithium-ion batteries cannot be extinguished with water. The vehicle burns completely. Up to now, the battery housings have been equipped with bursting discs, metal discs that break in the event of a strong increase in pressure and allow the gases to escape. The disadvantage: they cannot be tested. Metal parts may fly around.

“We have further developed the pressure valve, which has to be installed in the metal housings anyway,” Freter explains.

The valve compensates for pressure differences to the external pressure, which can occur with temperature fluctuations or changes in altitude. The Kayser valves have a diaphragm made of polytetrafluoroethylene. Gas exchange is possible through the fine pores of the plastic. However, dirt and water do not pass through.

If the pressure in the housing rises sharply, the valves fly out, but are held in place by an arm, Freter shows. He developed the first prototype of the “Kayser-Guard” with his team within five weeks. “The protective element is one of several product innovations from our New Energy Vehicles division,” reports Sales Manager Marc Wallrabenstein.

“Kayser was founded in 1765 by a wool dyer who produced clothing fabrics for the Prussian Army,” Wallrabenstein elaborates. Since 1960, the Einbeck-based company has been manufacturing for the automotive industry. Today, Kayser Automotive Systems produces, among other things, filters, valves, lines and air ducts, many of which are integrated into ready-to-install systems. The group, which is still family-owned, also includes the Kayser Filtertech Group, which specializes in textile filter media.

Research and development employs 200 of the Kayser Group’s total of 3,600 people. The “Kayser-Guard” protective element was jointly developed by the two companies.

Source reference: Northeimer Neueste Nachrichten from 08.07.2021, page 2